KRS-Bivitec Screen

High G-Force (up to 50 g’s)

Dry screening raw coal down to 3mm, drive speed is 800rpm

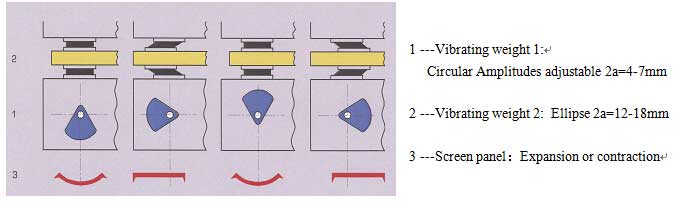

² Principle of Operation

The special feature of this screen is the dual vibration principle. With the aid of resonance, one drive provides two vibration movements that is a fundamental oscillation (rotating eccentric) and an overlaid vibration (floating deck). In this process, the screen panel continues expanding and contracting (over 800 times per minute) so achieve a high acceleration rates (up to 50 g) and prevent the screen panel openings from plugging.

² Applications

There are over 300 Bivitec screens currently dry screening coal at coal mines and steel mills in China, India, South Africa, Korea & Western Europe at cut points down to 3mm. There are over 2000 Bivitec screens currently operating worldwide in mines, rock quarries, steel mills, cement plants etc.- screening sand, aggregates, iron ore, limestone etc.

² Features

Ø Bivitec polyurethane screen panels are a special design which have a long service life.

Ø The drive speed is 800rpm, the acceleration to the material can be up to 50g.

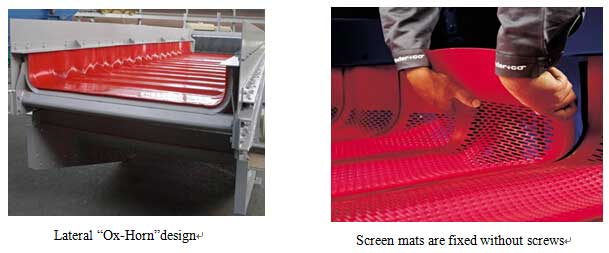

Ø Screen mats are fixed without screws guarantees a gentle screening as well as a fast change.

Ø Ox-horn design insures no wear of the side plates and no misplaced material in

the underflow.

Ø No need to clean the screen mats after shut down due to its good self-cleaning ability.

Ø The machine is seated on hollow springs made of rubber cause little noise and provide a high service life.

Ø Floating deck stroke is adjustable from 12 to 18mm.

Ø G-Force adjustable from 10-50 g’s .

Ø The cut point down to 3mm for coal or 0.2mm for other application.

Ø Less moving parts, high reliability, low maintenance, high availability.

² Machine Data

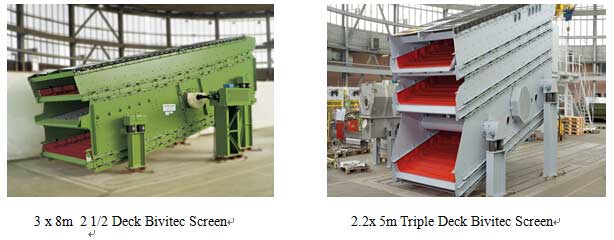

Ø Screen widths, fully usable from 400mm to 3600mm;

Ø Screen lengths, fully usable from 2m to 12mm;

Ø Machine weights from 1 ton to 25 tons;

Ø Driving power from 2kw to 55kw;

Ø Screen inclination from 5 degrees to 22 degrees;

Ø Single deck screens, double deck screens or triple deck;

² Steam Coal Plant Typical Flowsheet

Ø Higher Calorific Value Product Ø Higher Plant Yield

Ø Lower water consumption Ø Lower Plant energy requirement

Ø Eliminates Thermal dryers Ø Reduces dewatering equipment loading by 95%

Ø Very reliable and very low maintenance & operating cost