KRS-Feeder Breaker

² Principle of Operation

The feeder breaker’s function is to accept oversize material from the mine at its maximum rate and break the material into useable size for handling by continuous means or by loading equipment. The feeder breaker is made up of four components, hopper, conveyor, breaker and mounting for transporting to other locations. Hoppers are designed to allow continuous operation from the mine and feed the feeder breaker continuously, the conveyor or feeder is designed to feeder the breaker continuously at a rate compatible with mine production. The breaker reduces the mine material to correct size for handling. The mounting components provide for moving the feeder breaker, crawler for frequent moves, powered or non- powered, skids for longer term positioning and permanent locations.

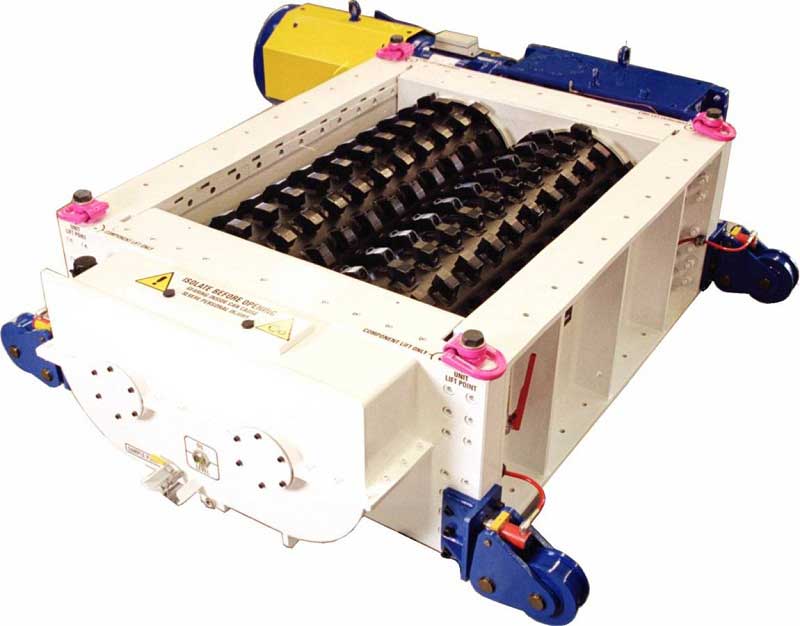

The feeder breaker is a single roll breaker that utilizes the feeder flights and the floor as a second roll. The feeder breaker because of its construction and technology fractures the material so to keep the amount of fines to the lowest in the industry. The feeder breaker only breaks oversize material and allows undersize to pass and therefore save energy and wear on the machine. The combination of the feeder and the breaker combined into one machine gives the end-user a very versatile and low cost machine for primary crushing.

² Type and Specification (Type based on rollers)

1. Single roll – feeder breaker

Ø Primary crushing, max. capacity up to 6,000t/h.

Ø Simple structure, reliable operation, low in power, fines, space, investment and cost, easy installation and

maintenance.

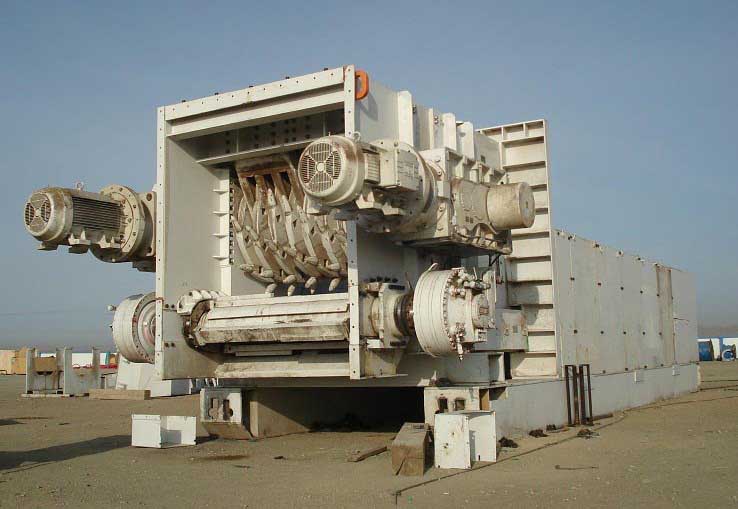

Ø Surface fully mobile feeder breaker for primary crushing, hydraulic crawler capacity up to 3500t/h.

Ø Surface semi-mobile feeder breaker on skids or non-powered crawler, capacity up 3500t/h.

Ø With or without hoppers

Ø Flat-back feeder breaker for surface applications. Surface crusher station, capacity up 6,000t/h.

Ø Underground feeder breaker, normally works with continuous miner and shuttle car.

Ø Pick breaker diameter up to is 70"

Ø Conveyor chain rated at 550,000 lbs.

Ø Pick forces approximatily140,000 Kg’s, pick force sized per the material hardness and application.

Ø Breaker speed is approximately 30rpm.

Ø Conveyor speed max 0.4-0.5 m/s.

Ø Max. Feeder size is1.8-2.0m.

Ø Product size is about 250mm or greater.

Ø Material hardness 200MPa.

![]()

2. Double roll crusher

Ø Secondary and tertiary crushing, capacity up to 10,000t/h.

Ø MVT (Matched Velocity Technology), minimizing the over crushing, optimizing structure, low in weight, low in

power consuming, reliable operating, low operating cost.

Ø Rolls centre distance: 600, 800, 1000, 1200, 1500, 1800mm.

Ø Roll length: 750mm, 1000, 1500, 2000, 2500, 3000, 3500, 4000mm.